When it comes to geophysics, few tools are as fascinating and effective as Vertical Seismic Profiling (VSP). Imagine peering deep into the Earth with a clarity that makes the underground world as familiar as your backyard—well, that’s what VSP makes possible. It’s not just another buzzword in the seismic realm; it’s a game-changing technology that allows scientists and engineers to image subsurface structures with exceptional detail.

So, why should you care about VSP? For starters, it’s vital in industries like oil and gas exploration, geothermal energy studies, and even environmental monitoring.

Basics of Vertical Seismic Profiling (VSP)

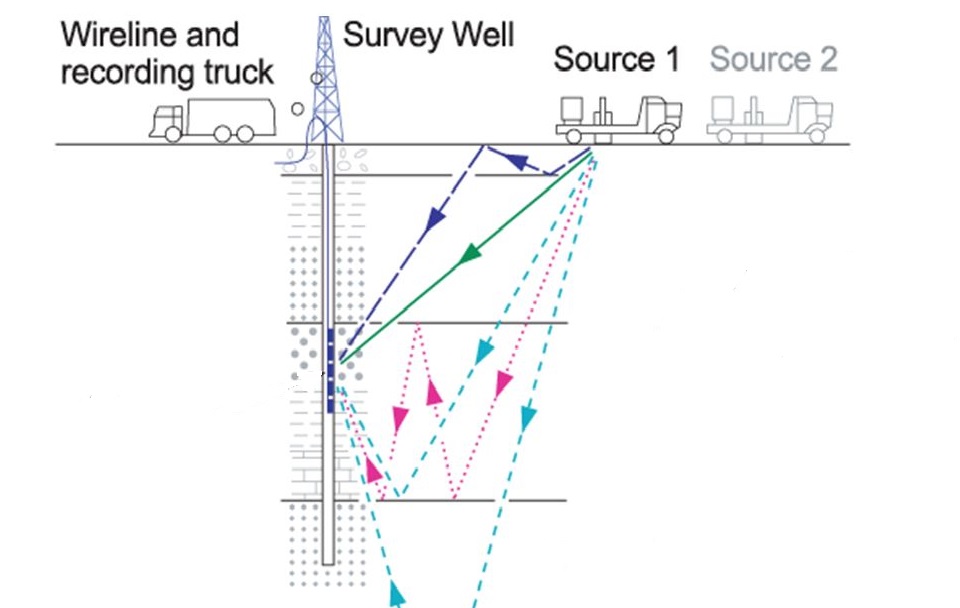

Vertical Seismic Profiling (VSP) is a geophysical method used to collect high-resolution seismic data from inside a borehole. It involves placing receivers, like geophones or hydrophones, down a wellbore and using a surface seismic source to generate waves. The waves travel through the Earth, interact with subsurface layers, and are then detected by the downhole receivers. This process provides a much clearer and more detailed image of the subsurface than traditional surface seismic methods.

Think of it this way: surface seismic methods are like listening to a conversation through a wall. You might catch the gist, but the details are fuzzy. VSP, on the other hand, is like being in the same room as the speakers—you hear every nuance and can even pinpoint where each sound is coming from.

Why Is VSP Important in Geophysics?

VSP stands out because it addresses several limitations of surface seismic methods. For example:

- Improved Resolution: Since the receivers are closer to the target layers, the data quality is significantly better.

- Direct Correlation with Well Logs: VSP data can be tied directly to well logs, giving geoscientists a more accurate picture of the subsurface.

- Noise Reduction: By placing receivers underground, VSP avoids much of the surface noise that plagues traditional seismic surveys.

These advantages make VSP a go-to method for understanding complex geological features, identifying potential hydrocarbon reservoirs, and even monitoring reservoir performance over time. Whether you’re a seasoned geophysicist or someone just dipping their toes into the field, the value of VSP is hard to overstate.

How Does VSP Work?

The Technical Process of VSP Surveys

Understanding how VSP works requires a step-by-step exploration of the process, from setting up the equipment to interpreting the seismic data. Let’s break it down into manageable chunks.

Step 1: Setting the Stage – Seismic Sources and Receivers

Every VSP survey begins with two key components:

- Seismic Source: This is typically a vibroseis truck, an air gun, or an explosive charge deployed on the surface. These sources generate controlled seismic waves that travel into the Earth.

- Receivers: Downhole geophones (or hydrophones in marine environments) are strategically positioned within a wellbore to detect these waves as they travel back.

Why downhole? Placing the receivers underground brings them closer to the target, ensuring that the data captured is high-resolution and less distorted by surface noise.

Fun fact: These geophones are so sensitive they can pick up subtle echoes from rock layers buried miles underground!

Step 2: Firing the Seismic Source

Once everything is in position, the seismic source is activated. The seismic waves propagate downward, interact with subsurface layers, and reflect or refract back. These interactions depend on the properties of the rock layers, such as density and elasticity.

Think of the seismic source as a flashlight and the Earth’s layers as mirrors. The waves (light) bounce off the layers (mirrors), revealing their shape and composition.

Step 3: Recording the Data

The downhole geophones capture these returning waves, converting them into electrical signals. Each geophone records a unique “time-distance” relationship between the source and the reflecting subsurface layers.

At this stage, the raw data looks more like a cryptic spreadsheet than a map. But don’t worry—this is where processing magic happens.

Step 4: Data Processing and Analysis

Processing VSP data involves turning those squiggly lines into meaningful images. Advanced algorithms and software clean up the data by removing noise, correcting for wave distortion, and enhancing resolution.

Key techniques include:

- Migration: Aligning the reflections to their true subsurface locations.

- Multiple Suppression: Removing echoes from previous wave bounces to clarify the image.

- Amplitude Analysis: Evaluating the strength of the waves to understand rock properties.

Here’s where things get exciting. Once processed, the data can reveal faults, fractures, and even the fluid content of reservoirs with astonishing precision.

Types of VSP Techniques

There’s no one-size-fits-all approach in VSP. Depending on the survey goals, different methods are employed:

- Zero-Offset VSP:

- The seismic source is placed directly above the wellhead.

- Best for imaging vertical sections and correlating with well logs.

- Offset VSP:

- The source is positioned away from the well.

- Ideal for investigating dipping layers or faults.

- Walkaway VSP:

- The source moves progressively farther from the wellhead.

- Useful for lateral imaging of reservoirs.

- 3D VSP:

- A grid of sources and receivers is used for three-dimensional imaging.

- Excellent for detailed reservoir characterization.

Real-World Case Study: VSP in Action

Consider a major oil and gas company exploring a new reservoir. Using a 3D VSP, they were able to:

- Identify a previously undetected fault zone.

- Map the extent of hydrocarbon-bearing sands with pinpoint accuracy.

- Save millions of dollars by optimizing drilling locations.

This example underscores why VSP is a favorite tool among geophysicists—it delivers actionable insights that translate into real-world value.

Types and Variations of VSP

Vertical Seismic Profiling (VSP) isn’t a one-size-fits-all solution. Its versatility lies in its various techniques, each tailored to specific objectives, geological conditions, and operational needs. Whether you’re imaging near-vertical layers or mapping vast lateral features, there’s a VSP method to suit the job. Let’s explore the most common types and how they’re applied in the real world.

Zero-Offset VSP

This is the simplest and most common type of VSP. In zero-offset VSP, the seismic source is located directly above the borehole, and the receivers are deployed along the wellbore.

Applications:

- Correlating seismic data with well logs to improve interpretation.

- Identifying subsurface layers and their properties with high accuracy.

- Imaging vertical sections of the Earth’s crust.

Advantages:

- Provides high-resolution vertical imaging.

- Excellent for calibrating surface seismic data to well data.

Limitations:

- Limited to imaging directly beneath the wellbore.

Think of zero-offset VSP as a zoomed-in snapshot directly below your feet—a perfect way to focus on what’s happening at the drill site.

Offset VSP

In offset VSP, the seismic source is placed some distance away from the borehole. This configuration allows the seismic waves to interact with subsurface layers at an angle.

Applications:

- Imaging dipping layers and detecting faults or fractures.

- Understanding lateral variations in rock properties.

Advantages:

- Provides more detailed imaging of inclined geological features.

- Extends the imaging range beyond the immediate vicinity of the well.

Case Example:

A geothermal exploration team used offset VSP to identify fracture zones critical for heat extraction, enabling them to target the most productive zones for drilling.

Walkaway VSP

Here, the seismic source is moved progressively farther from the wellhead, while the receivers remain stationary in the wellbore. The data collected from multiple offsets provides a lateral profile of the subsurface.

Applications:

- Mapping lateral changes in subsurface structures.

- Imaging beneath complex geological features like salt domes.

Advantages:

- Offers a broader view of the subsurface.

- Useful in exploring large reservoirs or faulted areas.

3D VSP

As the name suggests, 3D VSP creates a three-dimensional image of the subsurface by using an array of sources and receivers. This method is like a full-body scan for the Earth, providing unparalleled detail.

Applications:

- Detailed reservoir characterization.

- Understanding the geometry of subsurface features in complex geological settings.

Advantages:

- Offers comprehensive imaging of the reservoir.

- Helps in optimizing drilling and production strategies.

Time-Lapse (4D) VSP

Time-lapse VSP, or 4D VSP, involves repeating surveys over time to monitor changes in the reservoir. It’s like taking periodic snapshots of the subsurface to track its evolution.

Applications:

- Monitoring fluid movement in reservoirs.

- Detecting changes in pressure or saturation over time.

Advantages:

- Valuable for enhanced oil recovery (EOR) and carbon capture projects.

- Provides real-time feedback for reservoir management.

Comparison Table of VSP Techniques

| VSP Type | Key Feature | Primary Application | Strengths |

|---|---|---|---|

| Zero-Offset VSP | Source directly above borehole | Vertical imaging, log correlation | High resolution |

| Offset VSP | Source placed at an offset | Imaging inclined layers, fault mapping | Extends imaging range |

| Walkaway VSP | Moving source away from well | Lateral subsurface profiling | Broader coverage |

| 3D VSP | Array of sources and receivers | Comprehensive reservoir imaging | Unmatched detail |

| Time-Lapse (4D) VSP | Repeated surveys over time | Monitoring reservoir changes | Tracks dynamic subsurface changes |

Why the Variety Matters

The different VSP techniques allow geophysicists to adapt their surveys to specific challenges and goals. For instance, while a zero-offset VSP might suffice for calibrating well data, a walkaway VSP or 3D VSP is indispensable for large-scale exploration projects. These variations make VSP a versatile tool in the geophysical toolkit, capable of meeting the demands of diverse industries and environments.

Applications of VSP in Geophysics

Vertical Seismic Profiling (VSP) is a geophysical powerhouse, with applications that span industries and scientific disciplines. From guiding oil and gas exploration to assessing seismic hazards, VSP provides critical insights into the subsurface. Let’s explore how this versatile method is applied in various fields.

Oil and Gas Exploration

Why VSP is a Game-Changer in Energy Exploration

In the oil and gas industry, precision is everything. Drilling a well costs millions, so having detailed subsurface information is crucial to minimize risks and maximize returns. VSP excels here by providing high-resolution imaging of geological formations, offering clarity that traditional seismic surveys often can’t match.

Key Applications in Oil and Gas:

- Reservoir Imaging: VSP helps map the extent and geometry of hydrocarbon-bearing formations.

- Fault and Fracture Detection: Identifying potential structural traps or migration pathways.

- Direct Hydrocarbon Indicators: Analyzing seismic amplitudes to infer fluid content.

Example:

An offshore oil company in the Gulf of Mexico used 3D VSP to map a complex salt dome structure. The high-resolution data revealed untapped hydrocarbon pockets that surface seismic methods had missed, leading to a significant discovery.

Geothermal Energy Studies

Supporting the Renewable Energy Revolution

Geothermal energy relies on accessing heat from the Earth’s subsurface. VSP plays a vital role by identifying fracture networks and high-temperature zones critical for geothermal reservoirs.

Key Contributions:

- Locating zones with high permeability and heat flow.

- Monitoring fluid injection and heat extraction over time using time-lapse VSP.

- Mitigating drilling risks in areas with complex geological structures.

Fun Fact: Geothermal projects in Iceland have successfully used VSP to optimize well placement, reducing costs and environmental impact.

Seismic Hazard Assessment

Making Communities Safer

In earthquake-prone regions, understanding subsurface structures is essential for hazard assessment and mitigation. VSP contributes by offering detailed images of fault zones and stress fields.

Applications in Seismology:

- Mapping active faults to assess earthquake risks.

- Monitoring stress changes along fault lines.

- Studying subsurface conditions to design earthquake-resistant infrastructure.

Case Study:

Following a series of earthquakes in California, researchers used VSP to map the San Andreas Fault in 3D. The results provided new insights into how stress accumulates and propagates along the fault line, aiding in future risk assessments.

Environmental and Groundwater Studies

Going Beyond Energy

VSP’s ability to provide detailed subsurface images isn’t limited to energy exploration. Environmental scientists use it to monitor groundwater resources, track pollutants, and assess subsurface contamination.

Key Environmental Applications:

- Tracking the movement of contaminants in groundwater.

- Identifying aquifers and assessing their health.

- Monitoring subsurface CO2 storage sites for leaks or changes.

Real-World Impact:

A study in Canada used VSP to monitor carbon dioxide injection at a carbon capture and storage (CCS) site. The data confirmed that the CO2 remained trapped within the target formation, proving the technology’s safety and effectiveness.

Mining and Mineral Exploration

Finding Hidden Treasures

Mining operations rely on accurate geological maps to locate ore bodies and plan extraction efficiently. VSP aids in:

- Imaging deep mineral deposits.

- Mapping subsurface structures to guide drilling.

- Detecting faults that might impact mine stability.

Example:

In Australia, a mining company used VSP to identify a large copper deposit buried under volcanic rock. The detailed data saved the company from drilling multiple dry holes and accelerated the project timeline.

Why These Applications Matter

The diverse applications of VSP underscore its value across industries. Its ability to provide precise, high-resolution imaging ensures safer drilling, more efficient resource extraction, and better understanding of our planet’s inner workings. Whether it’s uncovering oil reserves, harnessing geothermal energy, or protecting groundwater, VSP is an indispensable tool for scientists and engineers alike.